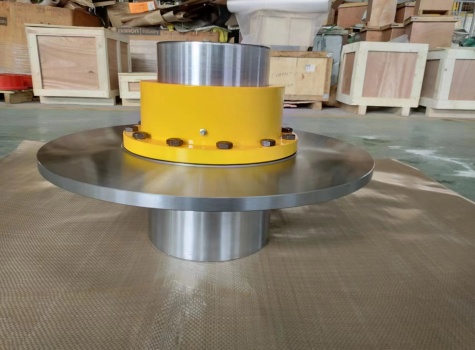

In the world of industrial machinery, where precision and reliability are non-negotiable, the choice of coupling can make or break operational efficiency. Introducing our state-of-the-art Diaphragm Couplings — engineered to redefine performance, minimize downtime, and elevate the productivity of your machinery.

At the core of our diaphragm couplings lies a design that marries strength with flexibility. Crafted from high-grade materials such as alloy steel and stainless steel, these couplings are built to withstand extreme temperatures, heavy loads, and harsh operating environments. Unlike traditional couplings that rely on elastomers or gears, our diaphragm couplings use thin, flexible metal diaphragms to transmit torque. This innovative design eliminates the need for lubrication, reduces wear and tear, and ensures zero backlash — a critical feature for applications demanding pinpoint accuracy, such as robotics, CNC machining, and precision manufacturing.

One of the standout advantages of our diaphragm couplings is their ability to accommodate misalignment. Whether it’s angular, parallel, or axial misalignment, the flexible diaphragms absorb and compensate for these deviations, protecting your equipment from unnecessary stress and extending its lifespan. This not only reduces maintenance costs but also enhances the overall safety of your operations, as sudden breakdowns due to misalignment become a thing of the past.

Durability is another cornerstone of our product. The metal diaphragms are precision-engineered to handle high torque levels without fatigue, ensuring consistent performance even in continuous, heavy-duty operations. Our rigorous testing processes — including vibration analysis, torque testing, and environmental simulations — guarantee that each coupling meets the highest industry standards for reliability and longevity.

Versatility is key, and our diaphragm couplings are designed to fit a wide range of industrial applications. From power generation and aerospace to chemical processing and automotive manufacturing, these couplings seamlessly integrate with various machinery, including motors, pumps, compressors, and turbines. We offer a comprehensive range of sizes and configurations, and can even provide custom solutions tailored to your specific operational needs.

Choosing our diaphragm couplings means investing in a product that delivers long-term value. With no need for regular lubrication or replacement of wear parts, you’ll see a significant reduction in maintenance time and costs. The improved operational efficiency, reduced downtime, and extended equipment life translate to a higher return on investment for your business.

At [Your Company Name], we are committed to excellence in every aspect of our products. Our diaphragm couplings are not just components — they are a testament to our dedication to innovation, quality, and customer satisfaction. Whether you’re looking to upgrade your existing machinery or outfit a new production line, our diaphragm couplings are the smart choice for precision, durability, and performance.

Elevate your operations with the best in the industry. Contact us today to learn more about how our diaphragm couplings can transform your machinery’s performance and drive your business forward.