In addition to providing its own brand accessories, H&C Group can also provide customized services based on drawings.

The raw materials, processing standards, and craftsmanship of H&C Group’s accessories are implemented in accordance with the highest international standards to ensure the excellent quality of the products and escort the operation of the customer’s on-site complete machine.

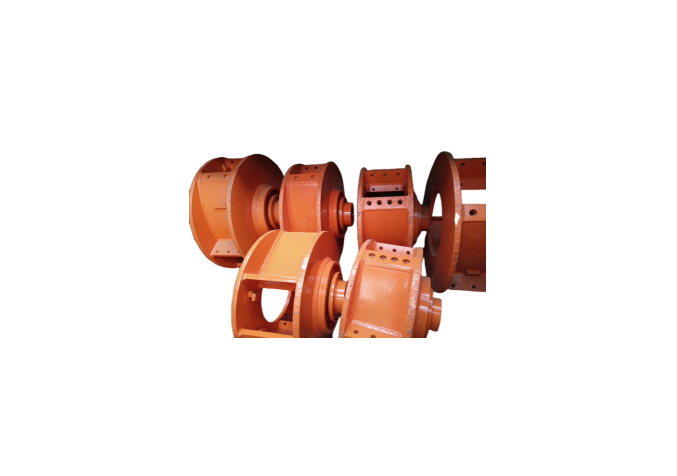

Sand making machine accessories mainly include impeller, wear plate, runner plate, throwing head and feeding barrel;

Main materials: high chromium cast iron, high manganese steel, new composite material, modified high manganese steel, new high manganese steel, ultra high manganese steel, super high manganese steel, metamorphic high manganese steel, multiple alloy steel, high (low ) chrome cast iron etc.

The wear parts that wear the most inside the rotor are the runner plate, throwing head, upper and lower wear plates and feed barrel. This is because these parts are always in direct contact with the stone material as it passes through the rotor. The runner plate wears in two ways, first by impact as the stone falls vertically into the rotor, and then by wear as the stone is ejected horizontally from the rotor at high speed. The throwing head is the last part that touches the material as it leaves the rotor. They have an ultra-high hardness carbide rod, which enhances its service life and improves the sand making effect. The lower wear plate usually wears more than the upper wear plate due to underutilization of the rotor, maximum production capacity and use of incorrectly shaped track shoes. The feed bucket is worn because it directs/funnels the stone into the rotor opening as it comes down from the hopper.