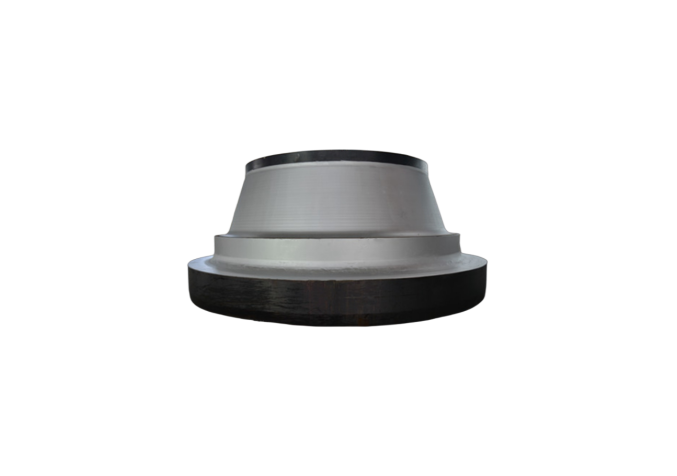

The vertical mill grinding table is one of the major components of the Vertical roller mill, components including the disc body, lining plate, briquetting, retaining ring, scraper plate, wind ring, air deflector etc. The main function of the grinding table is to support the material bed and transmit the force generated by the grinding roller to the lower reducer. In addition, it can transmit the torque of the reducer to the grinding area.

[Processing weight] 20-132T

[Major material] plain carbon steel/silicon manganese steel

Machining Strength:

Use water glass sand moulding technology to make the grinding table base uniformly stressed, and increase the bite angle between the grinding table and rollers to avoid erosion of the non-wear surface of the grinding table.

Non-destructive inspection will be carried out before the product leaves the factory, in case to ensure the high quality of the internal and external vertical grinding table and meet both customer requirements and industry standards.

Machining Flow

Casting simulation – wood mould making – pit modelling – molten steel smelting – material testing – metal founding – casting cleaning – heating treatment – polishing& finishing – shot blasting – machining – nondestructive testing – packaging & delivering